Sign up to our newsletter for exclusive offers!

Loading...

Checkout using your account

Checkout as a new customer

Creating an account has many benefits:

- See order and shipping status

- Track order history

- Check out faster

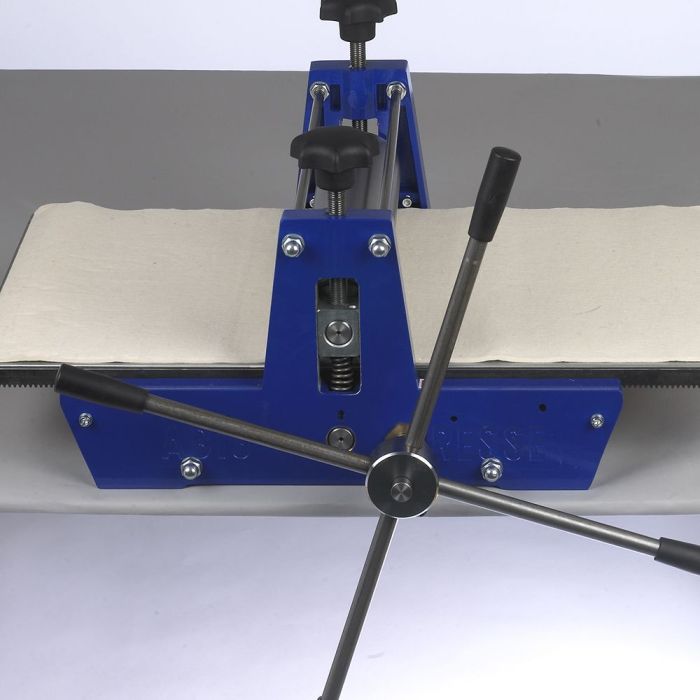

Gear Drive Replacement Plate Beds

Web Code:

Select an option

£399.00

£478.80

Incl. VAT

Incl. VAT

Incl. VAT

In Stock

The difference between these printing presses and the P690 presses is the gear drive.

Instead of the top roller providing a downward pressure and moving the plate, gears engage with the teeth on the underside of the plate bed.

This makes them not only great for lino, etching and wood blocks but also for collagraph and foam plates, such as QuickPrint, which can be crushed with too much pressure.

The 2:1 ratio gearbox makes the handle turn easily. The distance between the top roller and the plate bed can be adjusted to 18mm.

Requests for a 43mm capacity can be accommodated, please contact us for a quotation.

Professionally manufactured from cast aluminium and fitted with 80mm diameter steel pressure rollers giving a press force of 1000kg.

A 2.5mm thick zinc sheet covers the plate bed to ensure longevity and provide a smooth running surface.

Oil all the moving parts of the press from time to time to stop it from seizing up and to make it easier to run prints through the press.

Each press is supplied with a plate bed and felt blanket and four bolt holes for bench top fitting, instructions for fitting the turn wheel and for oiling the press correctly.

Please note: the additional delivery charge only applies to P693C and P693D, see Ts & Cs for more information.

Instead of the top roller providing a downward pressure and moving the plate, gears engage with the teeth on the underside of the plate bed.

This makes them not only great for lino, etching and wood blocks but also for collagraph and foam plates, such as QuickPrint, which can be crushed with too much pressure.

The 2:1 ratio gearbox makes the handle turn easily. The distance between the top roller and the plate bed can be adjusted to 18mm.

Requests for a 43mm capacity can be accommodated, please contact us for a quotation.

Professionally manufactured from cast aluminium and fitted with 80mm diameter steel pressure rollers giving a press force of 1000kg.

A 2.5mm thick zinc sheet covers the plate bed to ensure longevity and provide a smooth running surface.

Oil all the moving parts of the press from time to time to stop it from seizing up and to make it easier to run prints through the press.

Each press is supplied with a plate bed and felt blanket and four bolt holes for bench top fitting, instructions for fitting the turn wheel and for oiling the press correctly.

Please note: the additional delivery charge only applies to P693C and P693D, see Ts & Cs for more information.

This product is classified as an 'article' and therefore by law does not require a safety data sheet under current legislation.

- Price:

- Actual Price:

Loading...